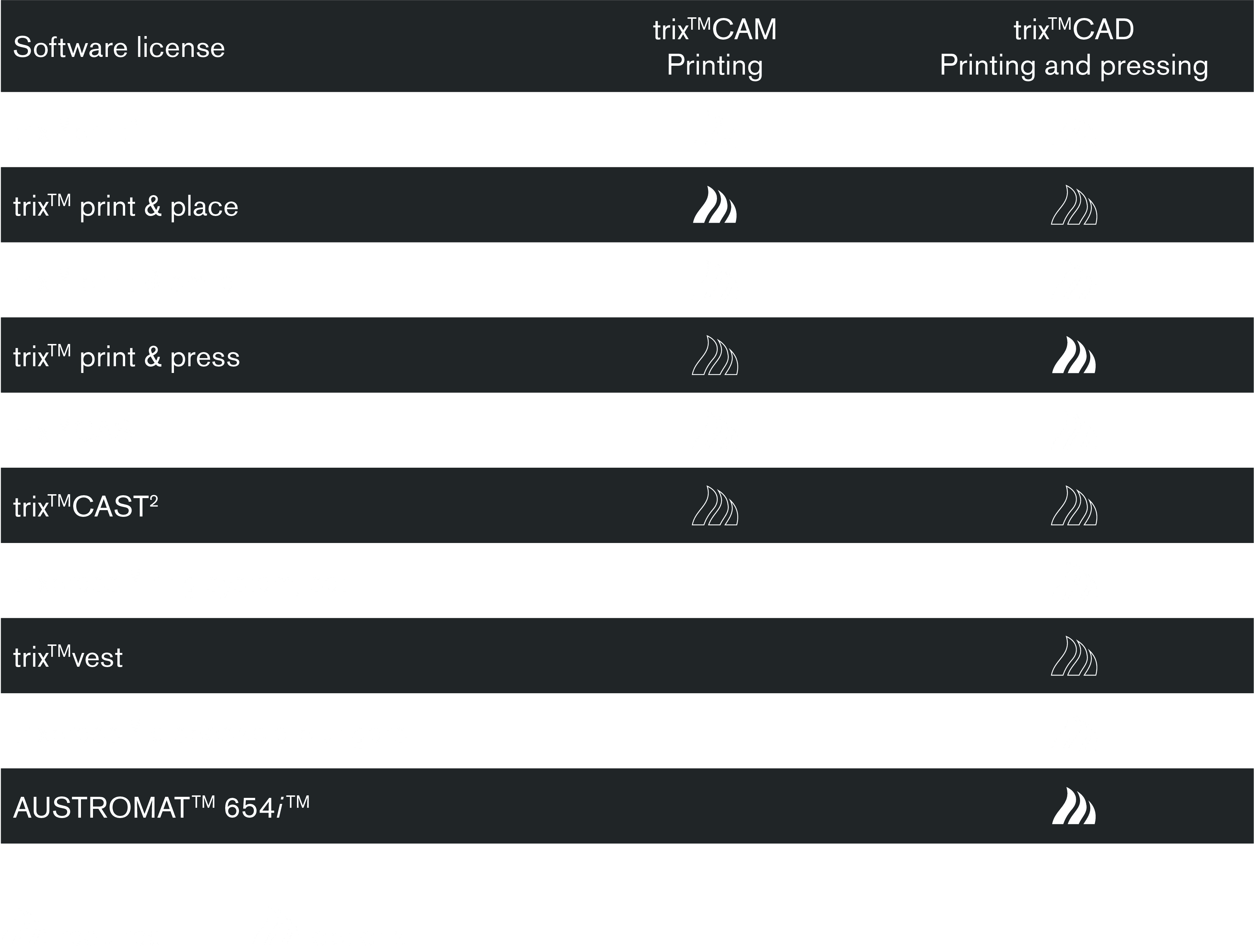

Digital Process Management for the

best results and the highest efficiency

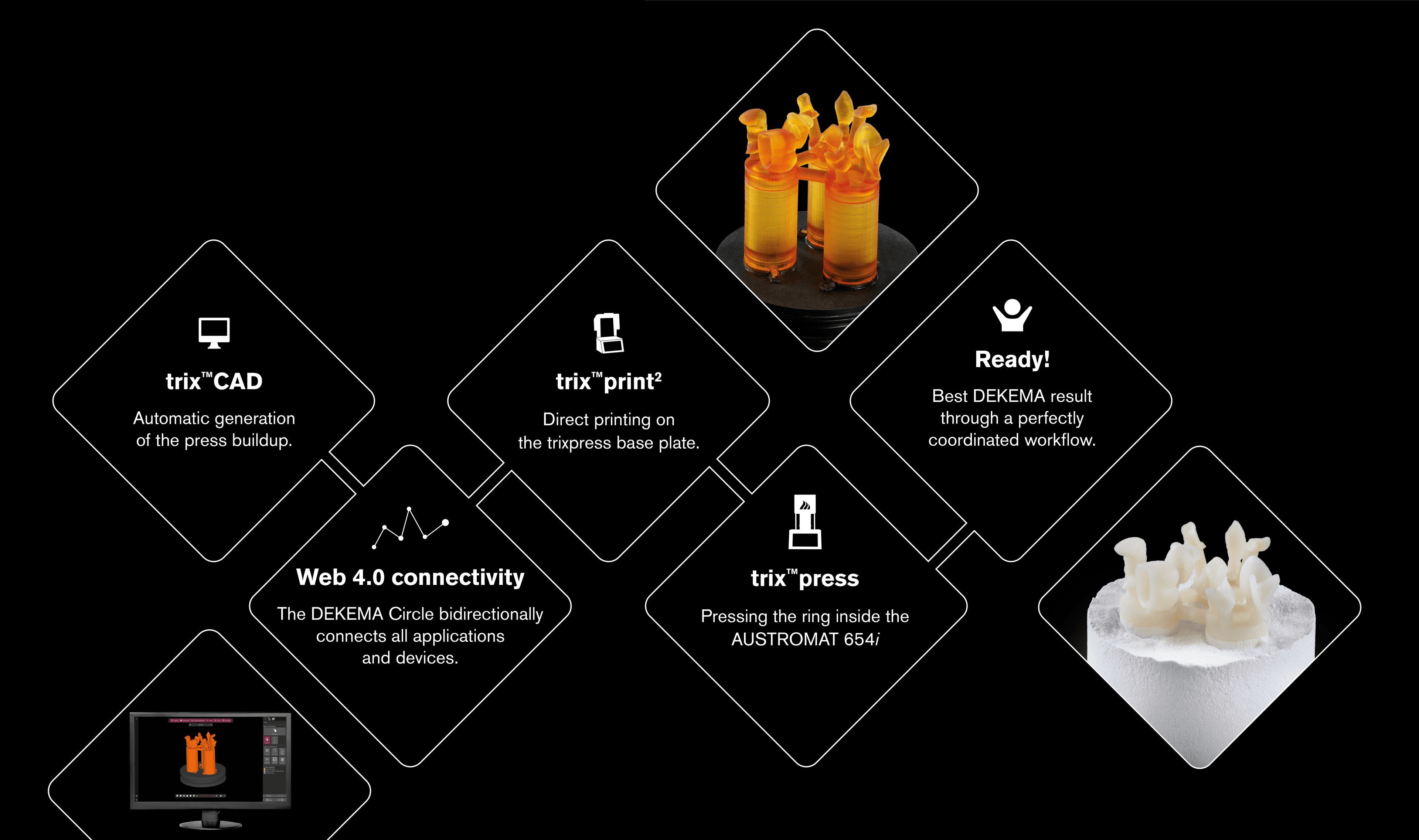

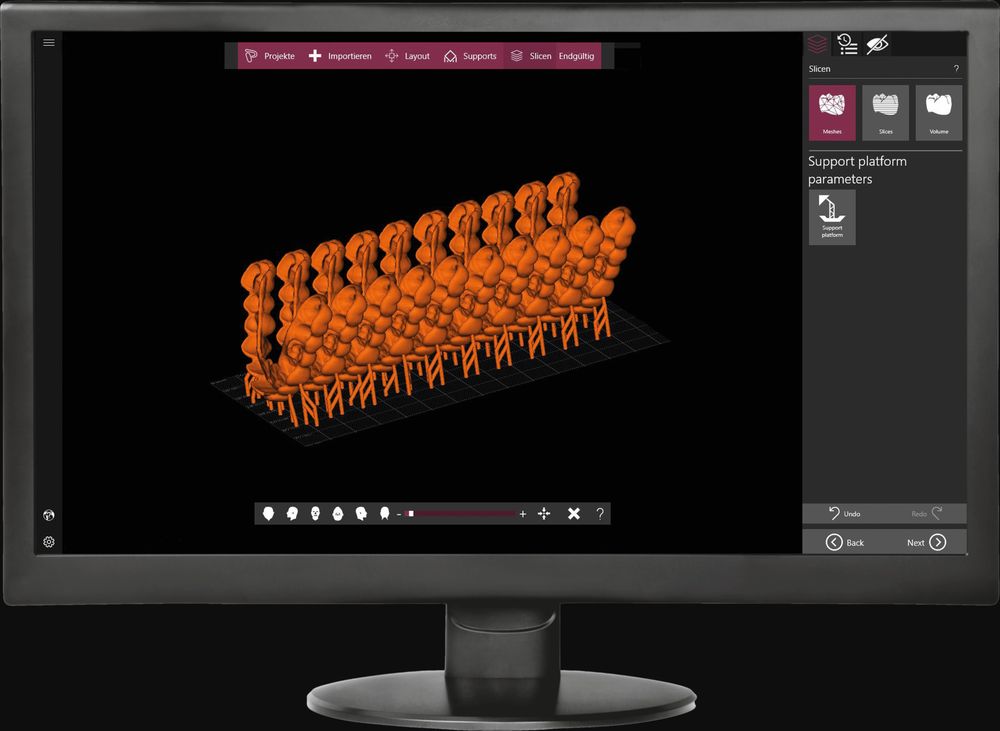

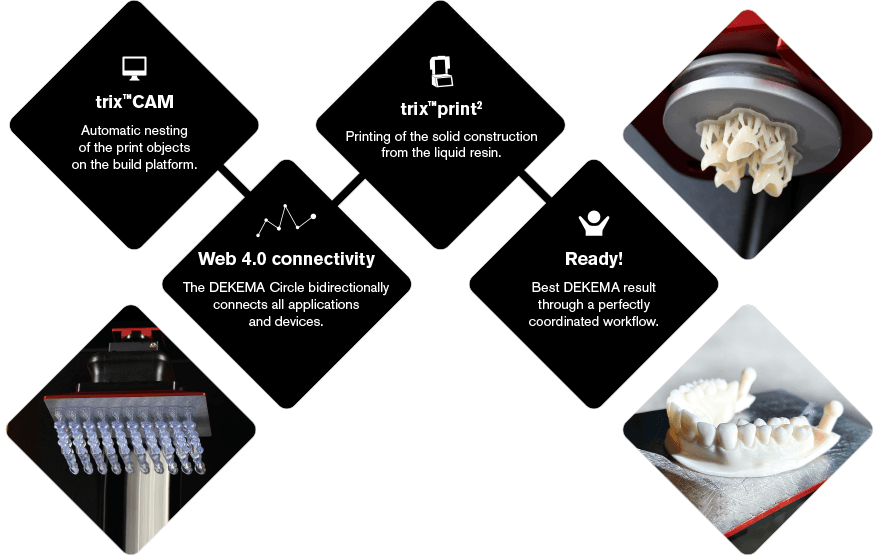

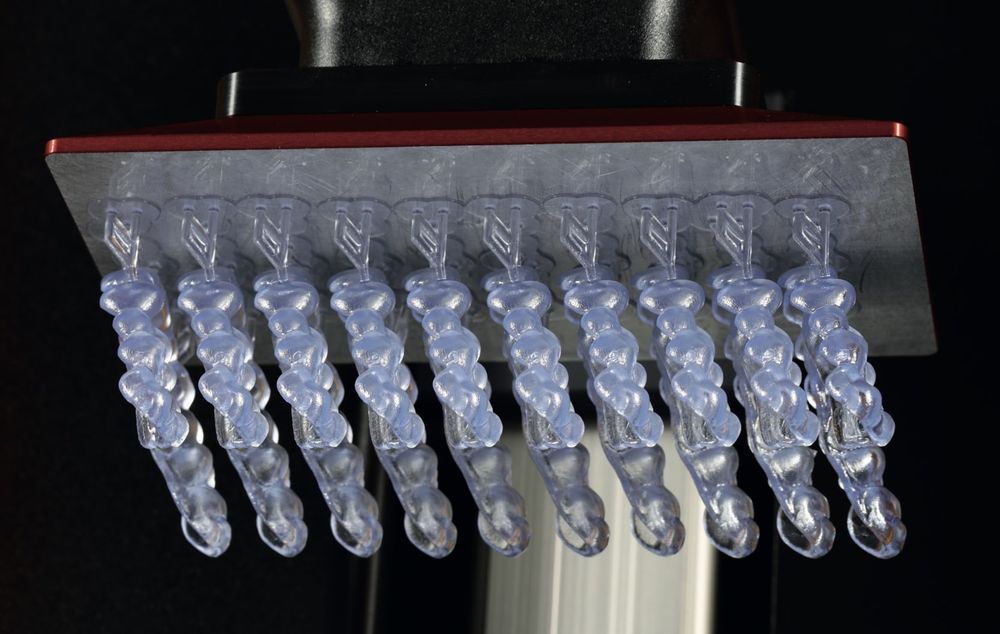

trix™CAD – The printing and pressing process

Selection and assignment of CAD press objects

Automatic setup generation

Slicing and data transfer to trix™print² via DEKEMA Circle